CDs emerged on the market several decades ago and quickly gained immense popularity. DVDs increased capacity, allowing for the storage of images and movies in addition to music. While CD or DVD duplication can be done at home, it is advisable to entrust this task to a professional pressing plant.

CD or DVD?

Before CDs, vinyl records were the primary medium for music. CDs were initially more expensive, but widespread production significantly reduced costs. While vinyl is an analog medium, CD audio is digitally encoded, and reading occurs not with a record player needle but through an optical laser.

A standard CD can hold 80 minutes of music, or other data, such as text files, with a capacity of 700 MB. DVDs look similar but have much greater capacity, making them commonly used for recording movies.

How to prepare a CD or DVD run?

Unlike vinyl, which is challenging to record at home, CDs are more accessible. All that is needed is a computer with an optical drive, a recorder, and blank discs. Computer programs available on the internet facilitate the burning of CD/DVD copies at home. While preparing a larger run this way may be time-consuming, it requires neither special skills nor a large budget. However, the downside is lower material quality and shorter disc lifespan.

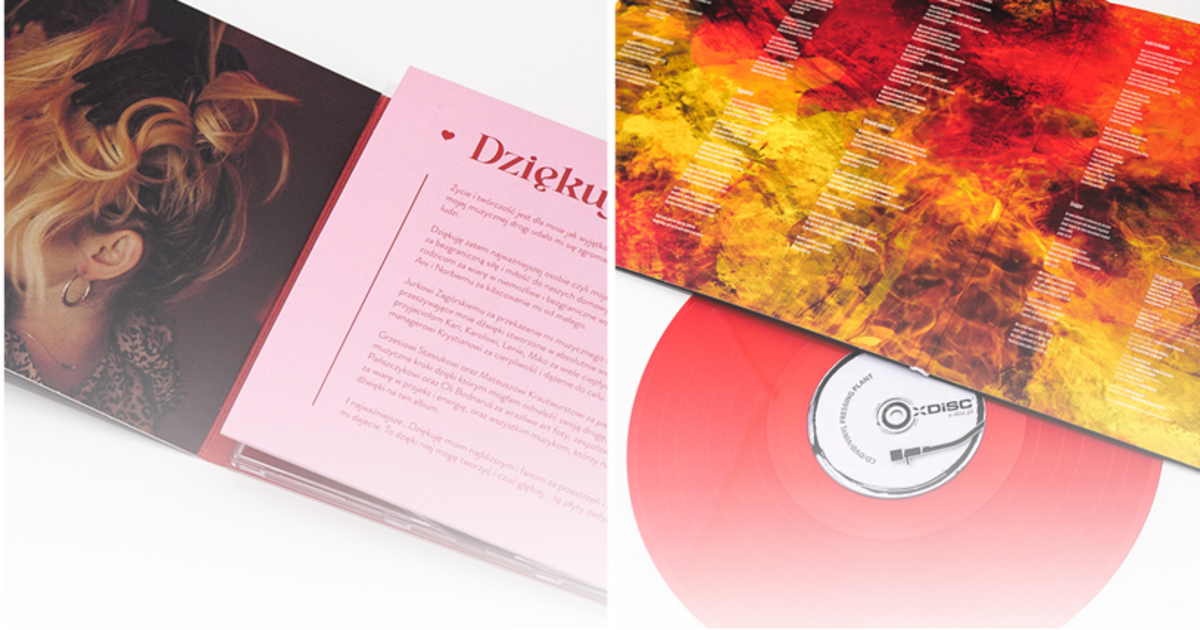

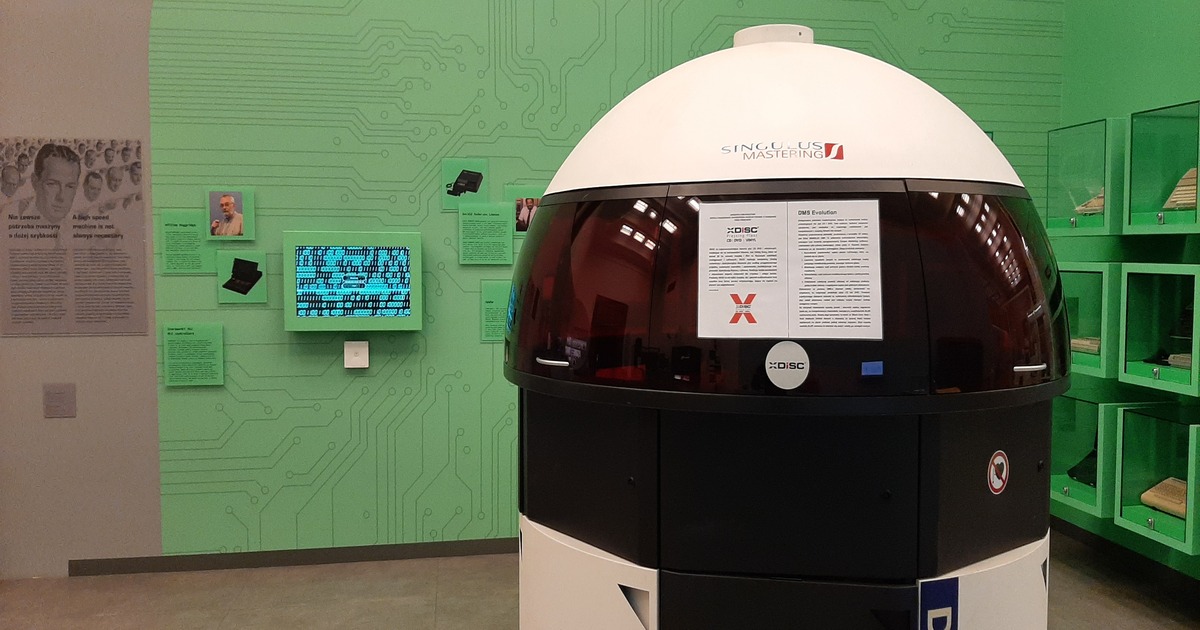

An alternative is professional CD/DVD pressing at XDiSC. The run can be of any size; you only need to provide the source material. After material approval, it is burned onto a glass disc with a photosensitive coating, known as glass. The next step involves placing the glass in an electroplating chamber, where a nickel layer forms on the disc. Nickel separates from the glass, creating a matrix, the foundation for the subsequent pressing process.

The pressing process differs from copying as the disc is formed from scratch in injection molding machines, molded under pressure from polycarbonate pellets. The pressed discs are protected with a layer of lacquer. Finally, the discs are adorned with commissioned graphics, packaged, and sent for distribution.