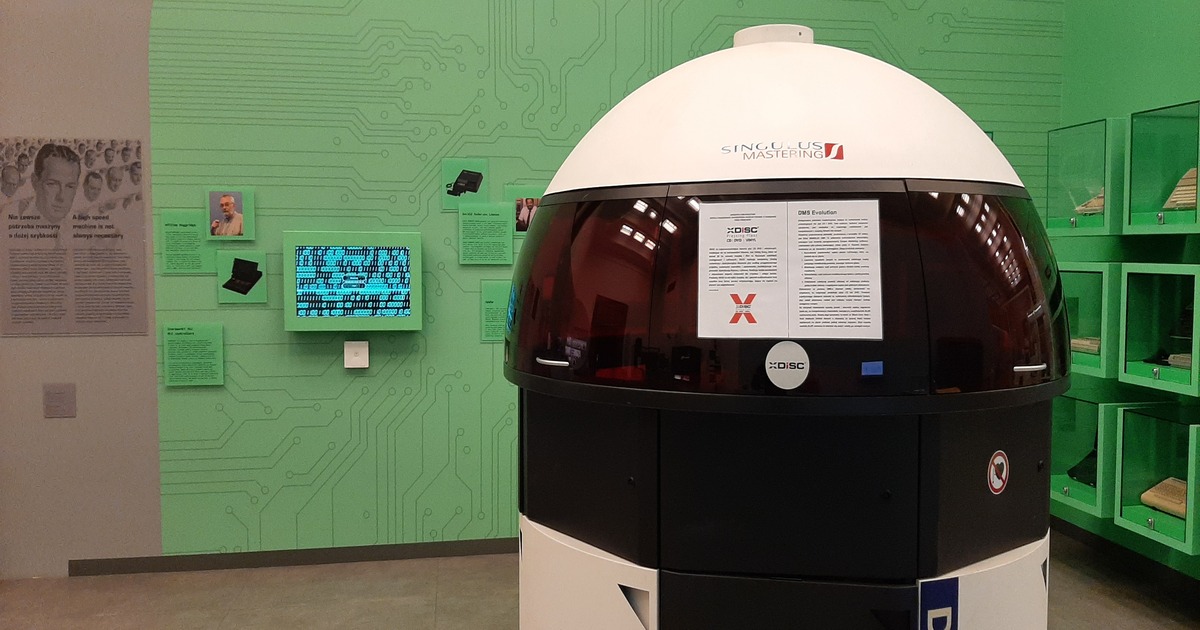

Compared to CD-R burning, CD pressing is completely professional media production method. The whole process takes place in an injection molding machine, where the discs are made of heated polycarbonate under high pressure in the mold. The matrix created during the mastering process is then imprinted into the disc.

How is a CD/DVD created?

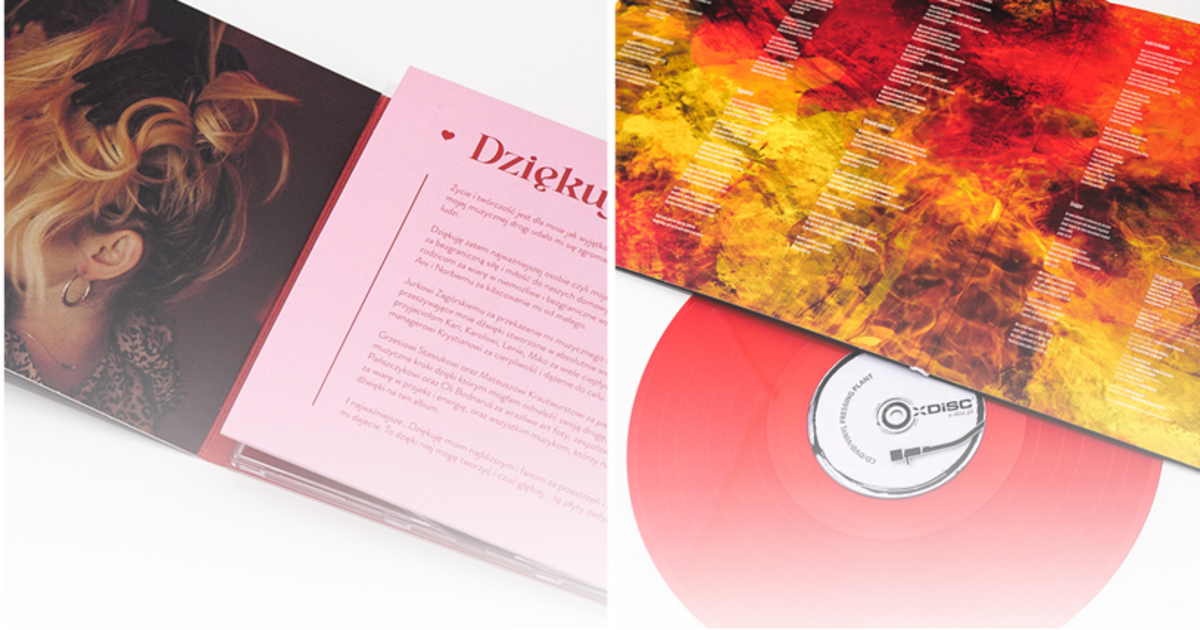

The production process of optical media begins even before the pressing plant. First, a matrix is created with the data that the disc will contain. It is for this purpose that the input material is taken from a physical carrier or from a disc image, it is burned on a glass disc (glass master), which is then metallized and galvanized. After the entire mastering and electroplating process is completed, the prepared matrix goes to the pressing plant, where the records are produced. The raw material for the production of CDs and DVDs is a special polycarbonate granulate, which, after drying and heating, is pressed under high pressure into a mold with a previously prepared matrix and formed into discs. After cooling, each plate is covered with a thin layer of aluminum, thanks to which the information contained can be read with a laser. The metallised surface is then covered with a UV-cured protective varnish. The final stage of pressing CDs and DVDs is an automatic quality control in the optical system, which checks the mechanical and electrical parameters of the pressed carriers. The resulting disc is ready for the next process, which is the imposition of an overprint by screen printing or offset printing.

What is a CD/DVD made of?

A CD is made of 90% of a material called polycarbonate on which the matrix was “imprinted” during the pressing process. Depending on the type of disc and application, aluminum, silver, brass and even gold are used as a reflective layer. In order to protect the CD, the CD is covered with UV varnish, which is additionally covered with UV ink, i.e. overprint. The DVD, on the other hand, contains UV glue because it is glued from two substrates.

Are CDs/DVDs permanent?

When the standard was introduced, the durability of records was estimated at several hundred years – this estimation was based on the assumption that no element of the player will have physical contact with the surface of the disc (as is the case with a gramophone record or magnetic tape), so it should rather not wear out. In the case of recordings made in the 1980s and early 1990s, these estimates changed, the estimated time was shorter, although the quality of the recordings was high at the time. With the spread of the standard and the decline in the prices of the discs themselves, their also quality decreased, which had a negative impact on the durability of the recordings – although for properly stored discs it could count for decades. Currently, it is estimated that CD/DVDs can last from several to several dozen years, depending on how users store and care for them.