The quality of the playback material depends on how the disc pressing process is carried out. Professional pressing looks completely different from burning CDs at home on a computer, resulting in a much higher quality and durability of the final product.

CD/DVD manufacturing – how should it be done?

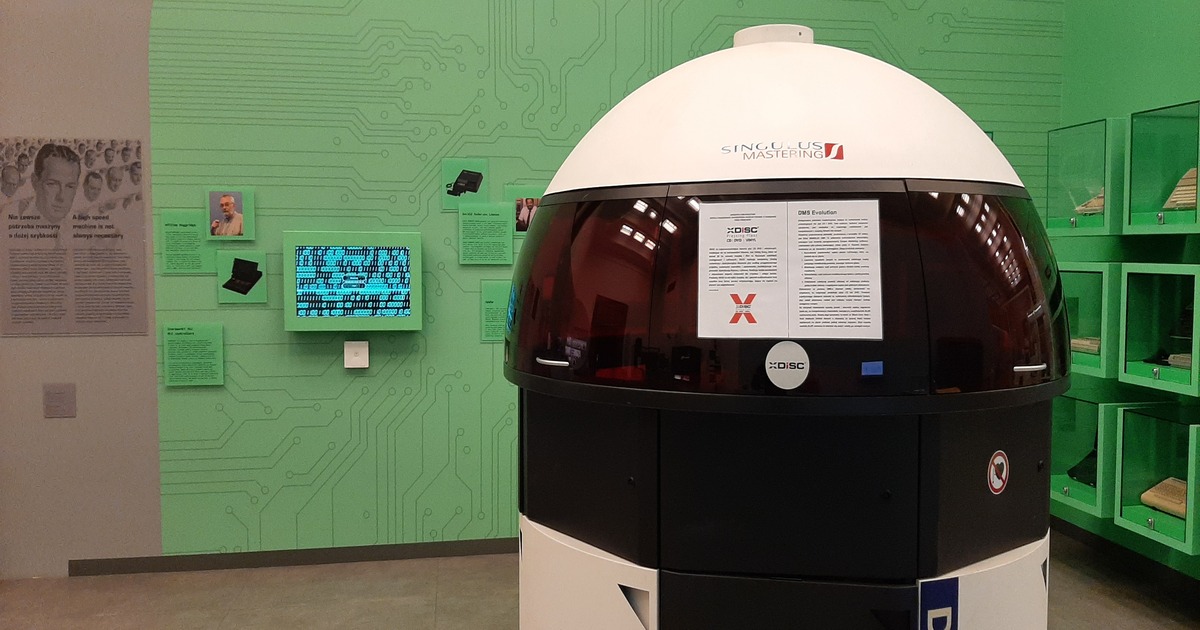

Pressing CDs and DVDs is a complex process, and the highest production standards must be maintained at every stage. It all starts with preparing the content that will go onto the discs – at XDiSC, the recording provided by the client is thoroughly checked to ensure it is correctly formatted and meets specific requirements.

Next comes the glass mastering stage. The content is laser-burned onto a glass disc coated with a photosensitive layer, which is then metallized. This creates a layer that precisely replicates the recorded material. The finished glass is placed in an electroplating chamber, where a layer of nickel is applied – the resulting metal matrix is separated from the glass.

It is crucial to thoroughly inspect the quality of the stamper at this stage, as the entire batch of discs will be pressed based on it. At XDiSC, the matrix undergoes rigorous testing for optical, electrical, and mechanical parameters.

Appropriate machinery park

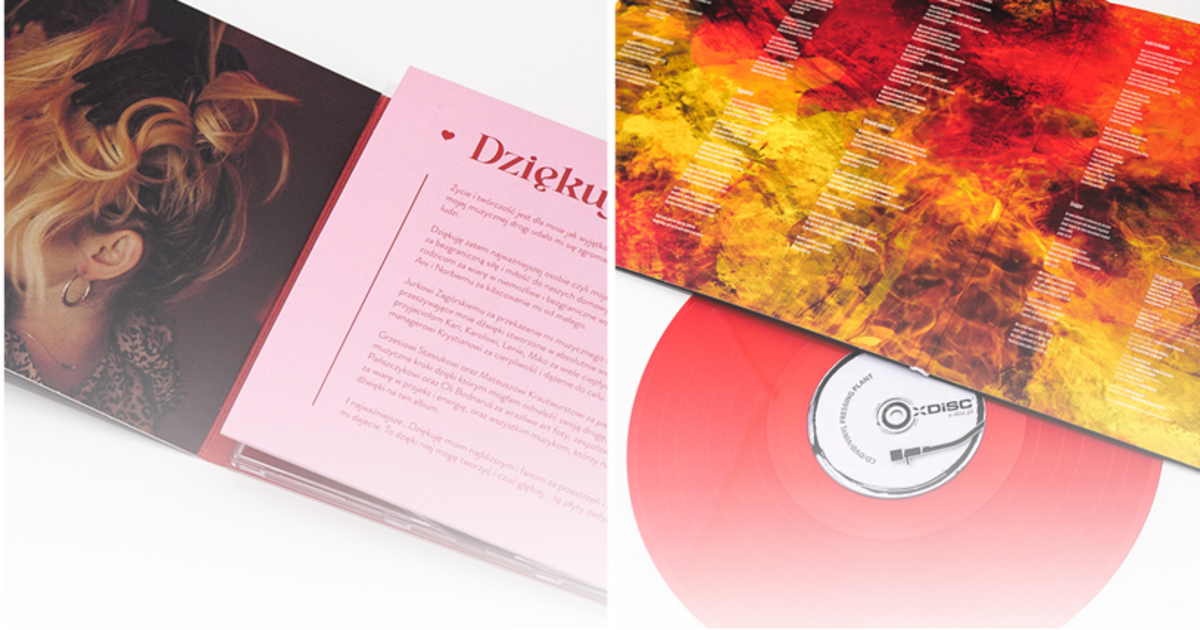

High-performance injection molding machines should be used for CD and DVD production. In professional pressing, the content is not recorded on pre-made discs; instead, they are formed under high pressure from polycarbonate crystals. The stamper with the source recording is immediately imprinted on such a disc – this way, a much higher quality material is obtained compared to home duplication. The disc is further finished with an aluminum layer and protective lacquer.

Why opt for professional disc pressing?

Pressed CD/DVD discs are far superior to duplicated discs. Their durability can reach up to a hundred years, which cannot be said for duplicated discs. During the pressing process, each disc has exactly the same material, and there is practically no loss of quality. In contrast, duplicating discs using recorders connected to computers often results in significant changes and more frequent errors during copying.