At XDiSC, the process of producing vinyl records is not shrouded in mystery! Check out below how we do it!

1️. Mastering – Music files used to create vinyl records must be of high quality. Therefore, 24-bit WAV files with a sampling frequency ranging from 44.1 to 192 kilohertz are needed. Files that do not meet this specification can be adjusted by XDiSC engineers during the mastering process.

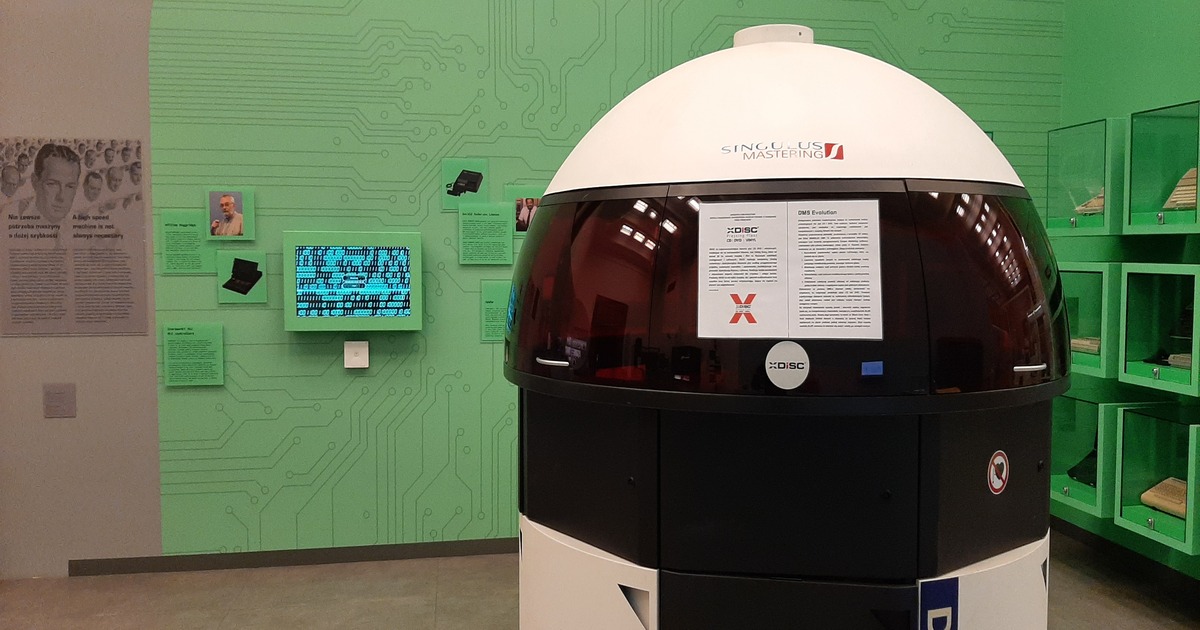

2. Cutting – Now, the digital sound needs to be transferred onto a mother plate. Using a special diamond cutting stylus on the copper surface of the plate, grooves are cut. These grooves represent the air vibrations emanating from the speakers. The cutting process lasts as long as the music on a given side of the record. There are only a few of these cutting machines in the world using the Direct Metal Mastering (DMM) technology! Finally, the catalog number, which will be stamped on the entire batch, is manually engraved. Now, using the mother plate, a matrix must be made, which will be used in vinyl pressing machines.

3. Galvanization – In a special bath in an electrolytic process, the surface of the plate is covered with nickel, filling the grooves. This creates a matrix, which serves as the negative of the mother plate.

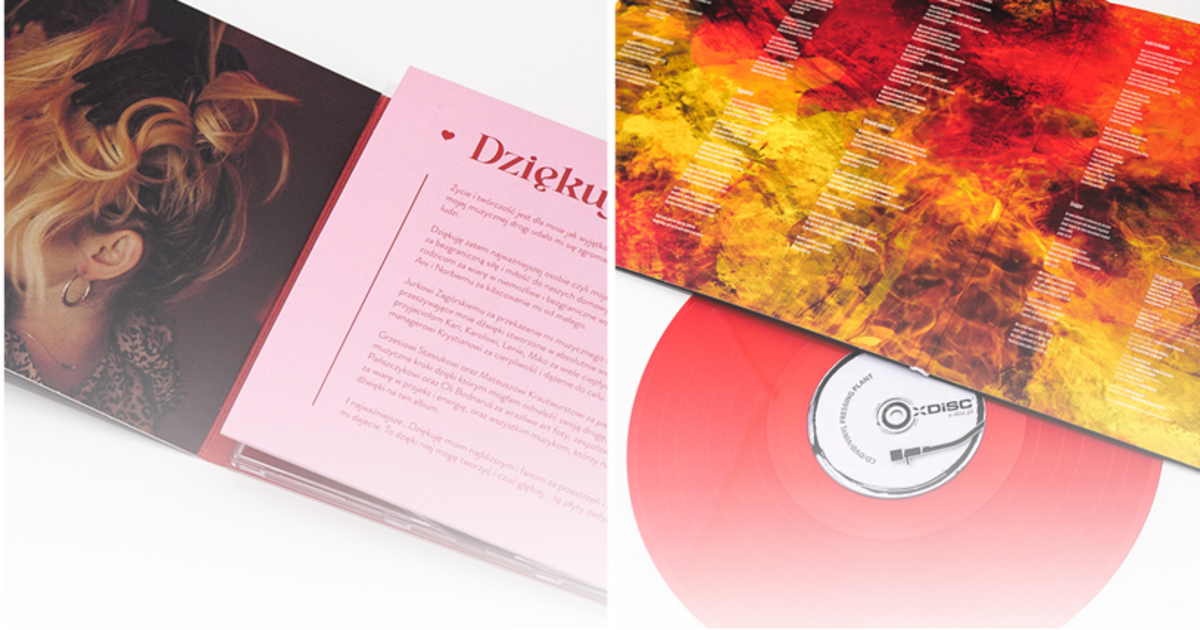

4. Pressing – After the matrices are installed in the pressing machines, polyvinyl chloride (PVC) is heated in an extruder to a temperature of over one hundred degrees Celsius, forming a so-called biscuit. The operator places it in the press and applies labels with information about the album and the artist. Under pressure and heat, the biscuit is squeezed between two matrices, the A and B sides of the record. The hot steam heats the vinyl, while cold water injected towards the end of the pressing process cools it, facilitating the removal of the finished record from the press. Excess material remaining after pressing is trimmed off. This surplus can be reused in the production process. Pressing each record takes about 30 seconds. Then, the vinyl records are left to rest for at least a day to avoid distortion.