In production, it is rare to be able to utilize raw materials in such a way that no waste is generated after creating the finished product. However, a significant portion of the waste can be reused, which helps reduce production costs and takes care of the environment.

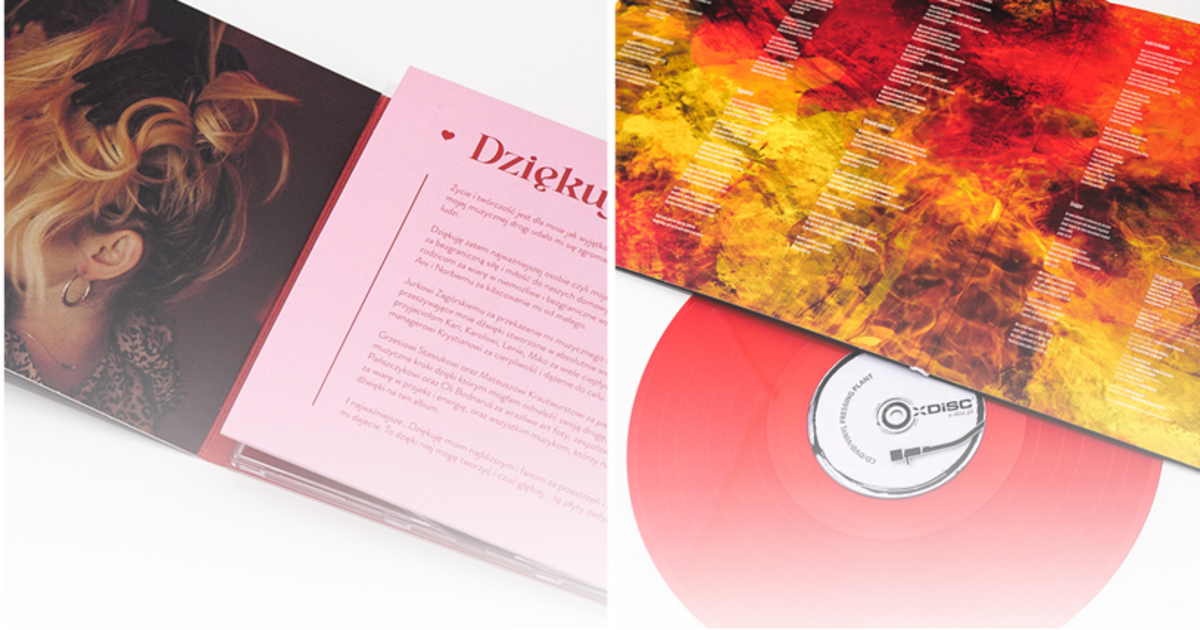

Ecological vinyl pressing

XDiSC is an eco-friendly company. The vinyl pressing process has been carefully planned to minimize waste generation. Waste materials are not simply discarded, as if any material is suitable for recycling, it is reintroduced into the production process, thus reducing the consumption of new raw materials. Even vinyl records that are not sold and treated as production waste find alternative uses – they can be transformed into wall clocks, coasters, decorative boxes, lamps, or interior wall decorations. These items don’t even have to be made from complete vinyl records, as leftover pieces from unnecessary CDs can be used to create mirror frames, vases, or other household trinkets.

Recycling production waste in the pressing plant is crucial because both vinyl records and CDs are made of plastics that take a very long time to decompose when thrown into the regular trash, making them unfriendly to the environment. Vinyl production has a significant carbon footprint, which is why XDiSC strives to reduce it by utilizing waste materials. Through eco-friendly production practices, the amount of carbon dioxide emissions and heavy metal pollutants released into the environment is minimized. The use of ecological (biodegradable) inks instead of traditional harmful dyes also contributes to maintaining a clean atmosphere.

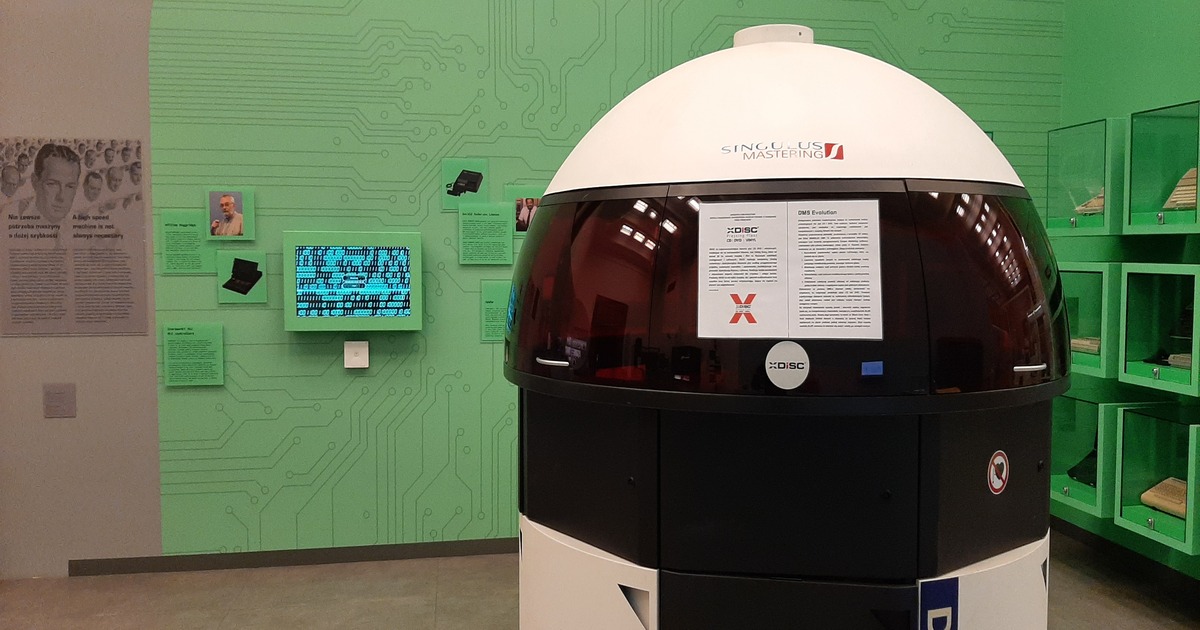

Lower energy consumption

The machinery in the pressing plant generates a significant amount of heat, so to avoid wasting it, XDiSC operates a modern energy recovery system that heats the offices on the company premises. The production lines also operate in energy-saving mode, consuming less electricity. A significant portion of the energy required to power the pressing plant is obtained from photovoltaic panels installed on the roof, which is a much more environmentally friendly solution than relying solely on the grid, benefiting both the environment and the people within it.